The "Safety Guardian" in high-risk scenarios: Johnson Controls Explosion-proof Electric Cylinders

Preface

In the control room of an oil and gas drilling platform, beside the reaction vessels in a chemical workshop, and in the working face underground in a coal mine - these high-risk environments that are flammable and explosive, any tiny electrical spark may lead to catastrophic consequences. The core component that supports the automated operation of these scenarios is precisely the explosion-proof electric cylinder that can "tame" danger. Today, let's have a good talk: How many hardcore technologies does this "security guard" in the industrial field actually hide?

One,What is an explosion-proof electric cylinder?

Ordinary electric cylinders may generate sparks during operation due to motor friction, short circuits, etc. This is not a big deal in normal environments, but in scenarios where flammable media such as gasoline vapor, gas, and acetylene are present, it is no different from "igniting". The core of explosion-proof electric cylinders lies in their special design to prevent "contact between sparks and flammable media", ensuring safe operation.

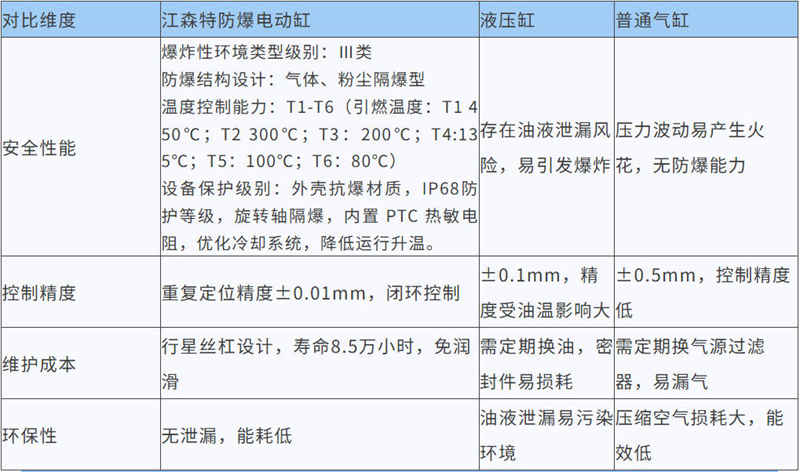

Two,Four Major Advantages of Explosion-proof Electric Cylinders

Three,none of these places can do without it

The application of explosion-proof electric cylinders has long permeated the "backstage" of our lives, especially in these key areas:

1、Chemical industry

Johnson Controls explosion-proof electric cylinders used for valve control in reaction vessels and material conveying robotic arms. With high-precision control, the valve opening and closing error is kept within 0.1mm, preventing safety accidents caused by material leakage.

2、The oil and gas field

In the throttle valve control and fuel distribution system of the drilling platform, it can withstand the high salt spray environment at sea and operate stably in extreme temperatures ranging from -40℃ to 80℃.

3、Underground coal mine

The propulsion mechanism is compatible with the roadheader. The flameproof enclosure can resist the impact of coal dust, and the intrinsically safe circuit avoids the risk of gas explosion.

4、Painting workshop

In an environment filled with paint vapor, drive the spraying mechanical arm to achieve precise operation. The spark-free design completely eliminates the risk of explosion.

Conclusion

As a manufacturing expert deeply engaged in the field of electric cylinders, Johnson Controls not only offers a full range of explosion-proof electric cylinder products, but also can adapt to the needs of different high-risk scenarios through customized design. At the 2025 China International Industry Fair, Johnson Controls explosion-proof electric cylinders have won extensive attention from domestic and foreign chemical and oil and gas enterprises with their dual advantages of "high precision + high safety".

Contact number:158 5027 2155

Official website:www.jstjmjxyxgs.com