|

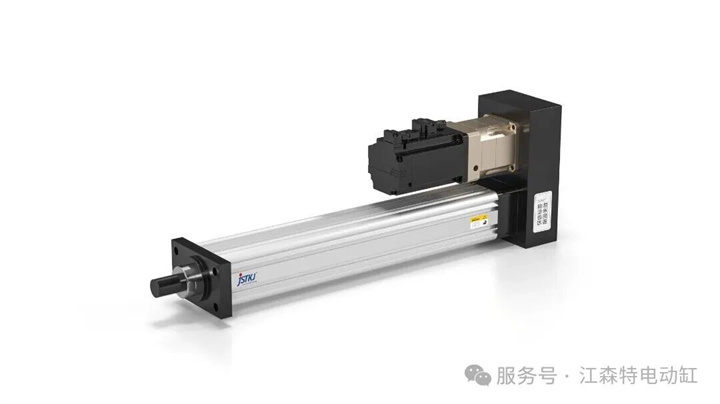

Electric cylinder |

Hydraulic cylinder |

|

|

Driving mode |

Driven by a servo motor, the rotational motion is converted into linear motion through a ball screw |

High-pressure hydraulic oil is provided by a hydraulic pump to drive the piston to achieve linear motion |

|

Structural composition |

Motors, ball screws, cylinder blocks, couplings, guiding mechanisms, etc |

Cylinder block, piston, piston rod, hydraulic valve, hydraulic pump, oil pipe, etc |

|

Control accuracy |

It features high positioning accuracy (up to ±0.01 to ±0.1mm), and can precisely control position, speed and thrust |

The positioning accuracy is relatively low (±1 to ±5mm for ordinary hydraulic systems), and a servo valve needs to be used in conjunction to improve the accuracy |

|

Environmental adaptability |

Suitable for various working conditions (high-temperature resistant, corrosion-resistant, low-temperature resistant, dust-resistant) |

Suitable for harsh environments (impact-resistant, sealed design can adapt to humidity) |

|

Control accuracy |

It features high positioning accuracy (up to ±0.01 to ±0.1mm), and can precisely control position, speed and thrust |

The positioning accuracy is relatively low (±1 to ±5mm for ordinary hydraulic systems), and a servo valve needs to be used in conjunction to improve the accuracy

|

|

Corresponding speed |

Fast (no delay in start, stop and speed change response), no influence of oil compressibility |

Slower (The oil is compressible, and a "crawling" phenomenon is likely to occur at low speeds) |

Contact

Hotline:400-996-7600

Address: No. 88 Zhenjiang South Road,

Ludu, Taicang, Suzhou City, Jiangsu Province, China

website:www.jstjmjxyxgs.com

mailbox:zhuang-xing@jstkj.net

QR code area

Scan and add WeChat

Scan the QR code and browse on your mobile phone